The benefits of working with 2D and 3D design software

The benefits of working with 2D and 3D design software

Developing Innovation: Creating products that stand out in terms of quality and efficiency

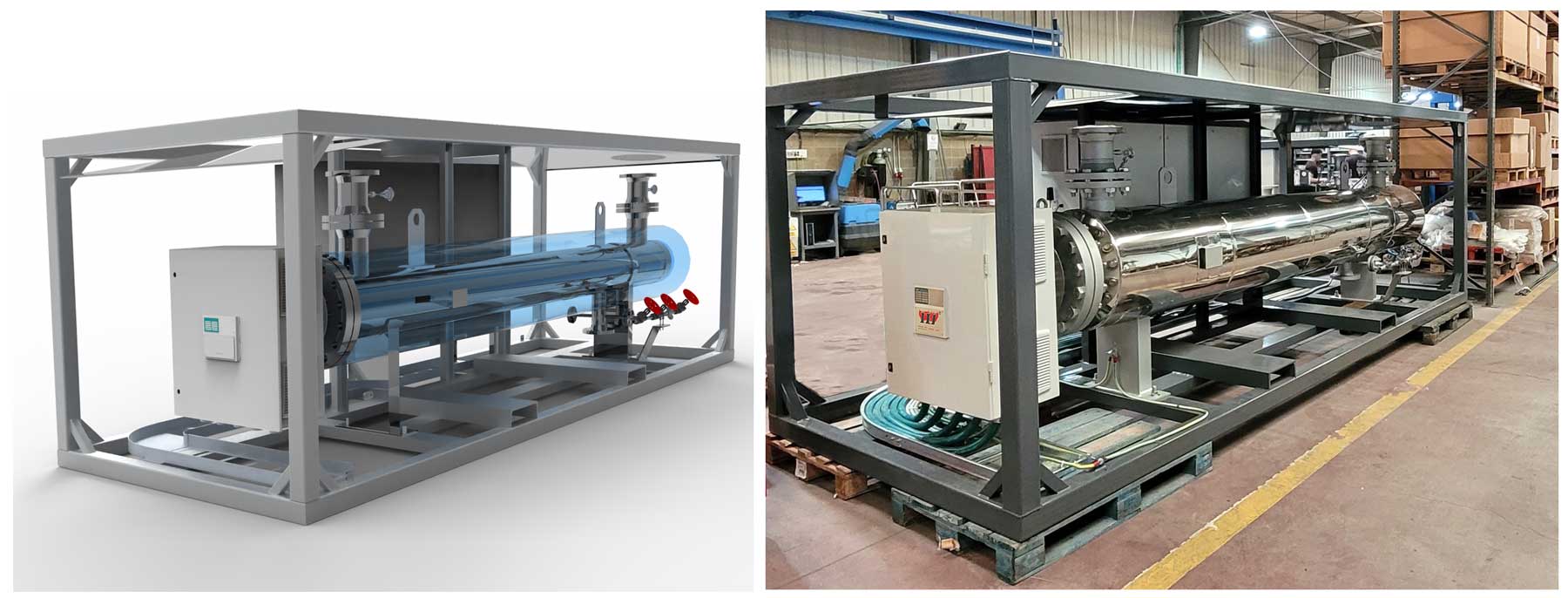

In recent years, IES Soler has experienced a significant transformation in its way of working, thanks to the integration of software into its creative processes and product development in 2D and 3D formats. Among these powerful tools stands out Solid Edge, a prominent computer-aided design software that has become a key element in the creation and optimization of more efficient and advanced equipment.

The application of this technology has transcended beyond simply improving the quality of products; it has also redefined the design process, providing greater agility and precision previously unthinkable. In a world where innovation and efficiency are decisive factors for success, these types of tools are an indispensable ally, bringing a series of benefits that positively influence both the development process and the final result of the products.

This technological integration has not only boosted productivity but also favored the creation of products with a high level of sophistication and performance. The ability to explore the limits of design thanks to 2D and 3D dimensions has opened new creative opportunities for IES Soler professionals, allowing them to push their vision and materialize ideas with exceptional precision.

In summary, working with 2D and 3D design software like Solid Edge at IES Soler means not only adapting to current times, but also taking advantage of the opportunities these tools offer to drive innovation and create products that stand out in terms of quality and efficiency.

Deciphering the Advantages: What are the benefits of working with Solid Edge or similar software?

- The first and most notable advantage of working with 2D and 3D design software is its ability to significantly reduce design errors. Thanks to its 3D visualization functionalities, designers can identify and correct any collision or assembly problems before they become real prototypes. This feature not only optimizes time and resources but also improves the quality of the final product.

- Another key aspect is the speed with which it allows designers to work. With an extensive library of parts and components, these tools facilitate the creation and modification of designs, thus accelerating the product development cycle. This improvement in design speed and efficiency is vital in a market where time to market can be a critical factor.

- Effective communication of design information is another strength of this type of tool. The software allows sharing design details through formats such as .step, detailed plans, and exploded views. This not only facilitates internal collaboration among teams but also improves the presentation and understanding of projects to clients and suppliers

- Additionally, there is the possibility of complementing basic design with advanced tools, like the frame function, perfect for creating chassis and other machinery components. This versatility of tools enriches the creative process and allows designers to explore new possibilities and solutions.

- Finally, the integration of tools like FloEFD, which focuses on fluid and thermodynamics analysis, allows users of this type of software to go beyond purely electromechanical design. This ability to integrate thermodynamic simulations into the design process offers a more comprehensive view of how products will function in real environments, thus increasing their reliability and performance.

In summary, adopting this technology represents a crucial advance towards efficiency, innovation, and excellence in the field of industrial design. Integrating these technological solutions allows companies to optimize processes, improve the quality of their products, and foster a more creative and productive work environment. This digital transformation not only increases competitiveness in the market but also promotes sustainable development and greater adaptability to changes in the sector. Incorporating this technology is, without a doubt, a fundamental step to stay ahead in an increasingly demanding and dynamic industrial world

Exploring the Integration of Tools in Industrial Engineering: Interview with Marcel Ruscalleda

Today we sit down with Marcel Ruscalleda, manager and technician of the Engineering department at Industrias Eléctricas Soler. With solid training in regulation and control of automatic systems, and a degree in Electronic and Automatic Engineering, Marcel has dedicated his professional career to the design of equipment, skillfully using different tools, among them, Solid Edge.

His academic and professional experience has kept him closely linked to sheet metal design, orderly technology, and synchronous technology design. This dedication has contributed significantly to improving the performance and effectiveness of the use of these tools in his daily work.

We talk with him about the utility and integration of these types of tools in the day-to-day of an industrial engineer.

What are the most important benefits you experience in working with 3D design tools, like Solid Edge, and their transition to 2D plans?

What are the most important benefits you experience in working with 3D design tools, like Solid Edge, and their transition to 2D plans?

It’s a tool that brings notable efficiency to our work. It allows us to avoid collisions, ensure the perfect integration of parts, and facilitate the creation of larger assemblies. In addition, the transition to 2D plans speeds up the process and reduces errors, as we can perform more complex calculations that would be difficult manually.

From your perspective, what functionalities of Solid Edge do you consider essential for IES?

What I like most about this tool is the 3D editing of synchronous technology. It offers flexibility, you can use it in ordered technology (providing gradual instructions as you progress in the creation of parts) or synchronous (flexible and can be modified more dynamically). Synchronous technology has allowed us to add more speed and performance to our design.

In conclusion, the use of advanced 2D and 3D design software can revolutionize work in engineering and industrial design, providing precision and efficiency.

At Industrias Eléctricas Soler (IES), the use of various tools, such as thermodynamic calculation software and mechanical design software, significantly improves precision in the development of products such as electric heaters. These tools not only prevent design errors, accelerate the development cycle, and improve communication and collaboration, but they also open the door to innovations and creative solutions.

Integrating technologies is undoubtedly driving progress in modern engineering.