The evolution of technical drawings

The evolution of technical drawings

From the drawing board to the digital model: the evolution of technical drawings in industry

For decades, technical drawings have been the central axis of any industrial project. Through them, equipment, installations and systems have been designed that have driven European technological progress.

At IES Soler, these documents have accompanied our trajectory from the forties to the present day, reflecting the evolution of a way of working that has gone from manual craftsmanship to digital precision.

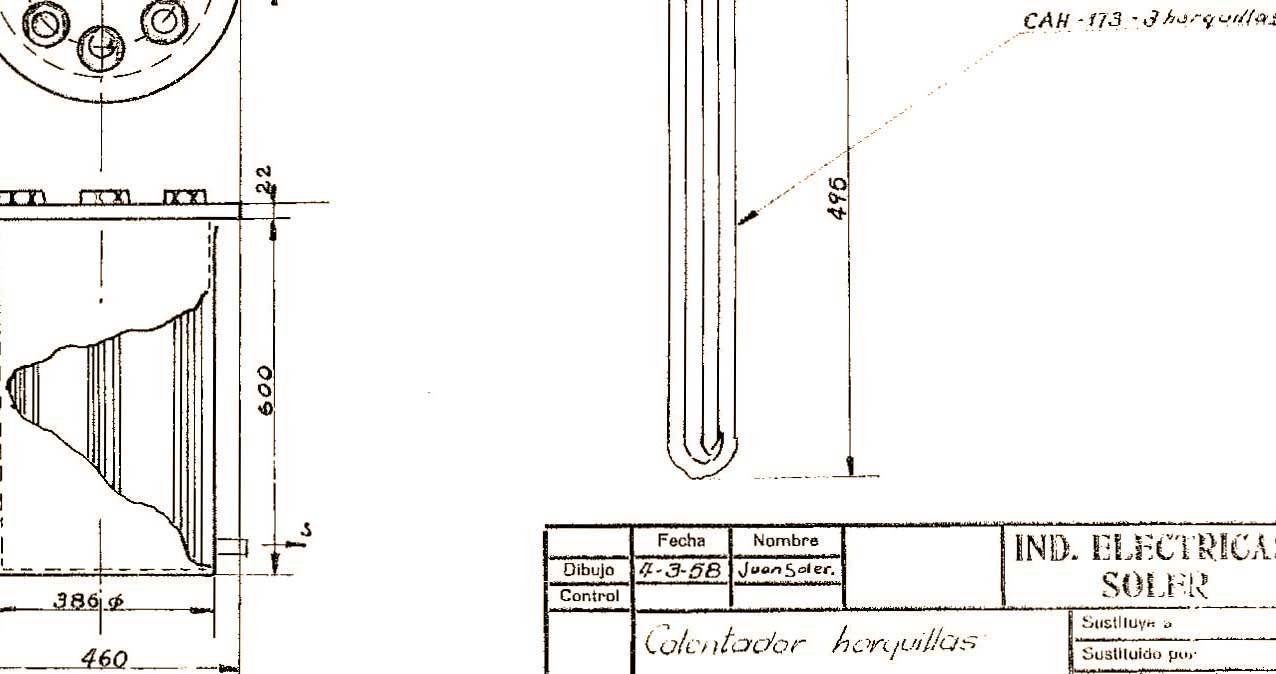

The beginnings: manual precision and artisanal talent

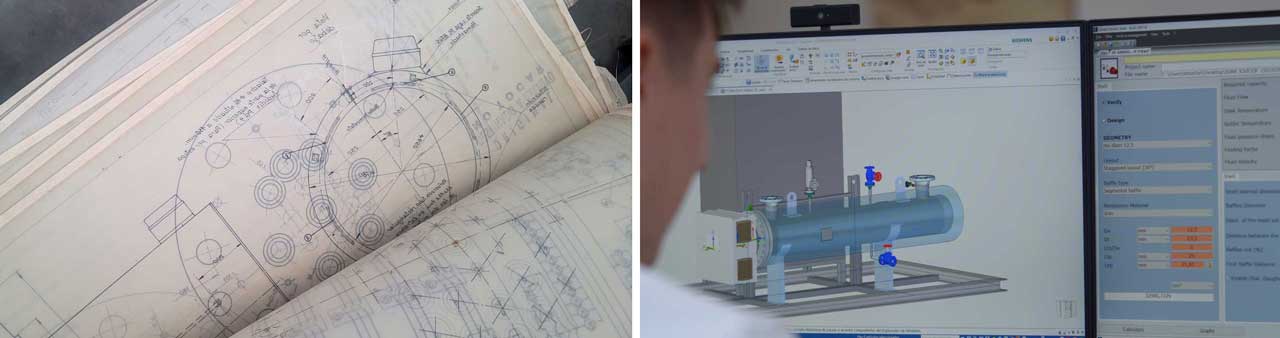

In the early years of IES Soler, plans were drawn by hand on tracing paper or technical cardboard, using rulers, compasses, straightedges and geometric patterns. Each line represented hours of meticulous work and great manual skill. This methodology, typical of the era of the industrial revolution, was based on orthographic projections and standard scales to ensure compatibility between parts and components. As BCAD Engineering states in its article on the history of technical drawing, “manual precision was the foundation of mechanical development until the arrival of the computer”.

The physical archives of those plans, many of which are still preserved at IES Soler, represented a treasure trove of technical knowledge, but also a limitation: any correction or update involved redrawing the entire document.

The arrival of CAD: the digital leap that changed everything

With the popularization of computers in the eighties and nineties, the industry experienced a real revolution: the incorporation of CAD (Computer-Aided Design).

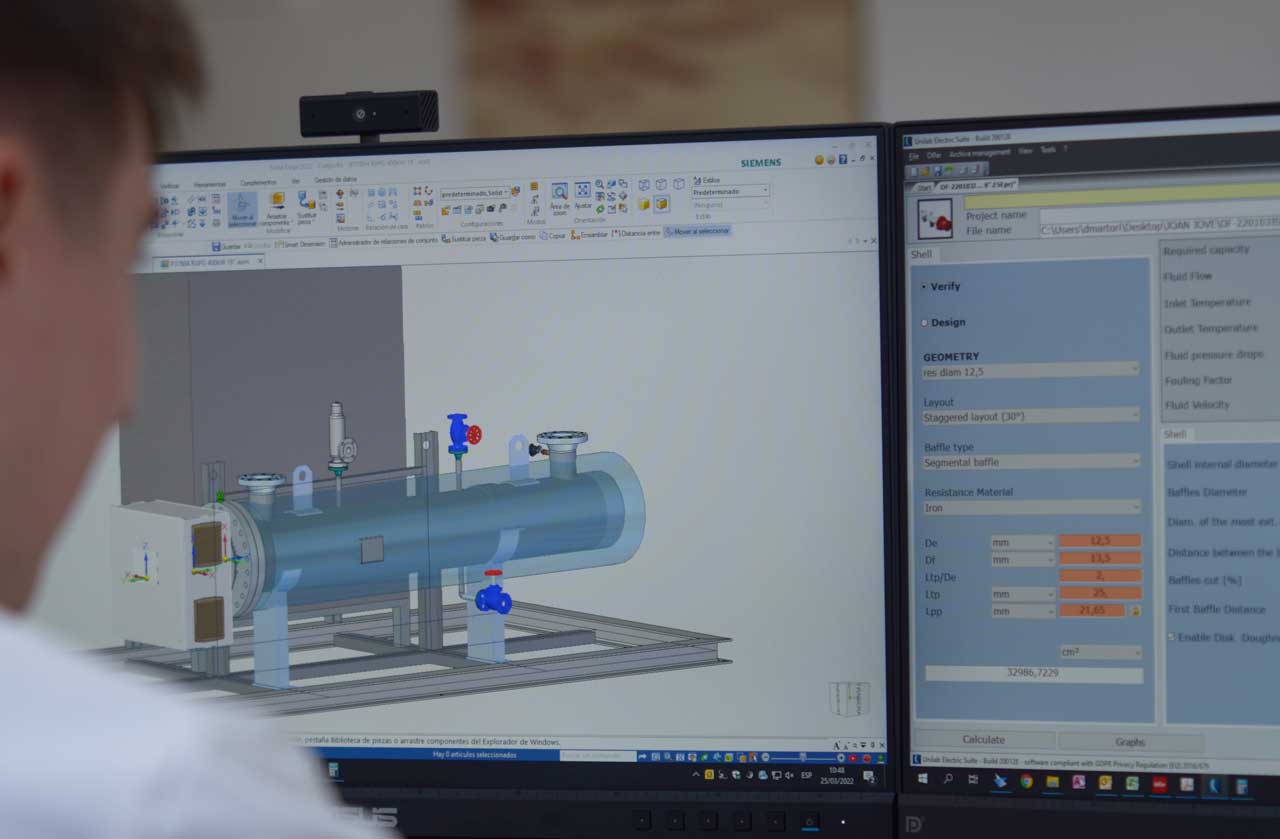

Tools such as AutoCAD or Solid Edge allowed drawing and modifying plans with a speed and precision unimaginable until then. According to a study published by the University of Târgu Jiu (Stăncioiu, 2024), CAD completely transformed the design cycle, reducing human errors and opening the door to digital collaboration and three-dimensional modeling.

At IES Soler, this change marked a before and after. Thermal projects, electrical diagrams and industrial resistor designs went from paper to digital files, allowing instant revisions, automated versions and full traceability of components.

From 2D drawing to 3D model: towards a more integrated industry

Today, technical drawings are no longer just static documents, but intelligent digital models. Their evolution towards 3D has allowed us to simulate thermal behavior, fluid flows with FloFED or structural forces before manufacturing a single piece. In addition, integration with other technologies, such as BIM (Building Information Modeling) or additive manufacturing (3D printing), has made drawings part of a complete digital ecosystem.

In the case of IES Soler, this evolution has translated into more agile projects, with greater precision and adapted to the sustainability standards demanded by today’s industry.This year 2025, the company has reached the 40,000 plane, an outstanding achievement that marks not only our production capacity, but also the efficiency and quality of our projects.

Artificial intelligence: the new chapter in technical design

The last stage of this evolution arrives with artificial intelligence applied to technical design. Today it is already possible to generate automatic sketches, plans are starting to be made with AI. This helps detect inconsistencies between plans or optimize components according to weight, cost or sustainability criteria.

This technological advance not only speeds up the work of engineering teams, but also democratizes access to advanced design, allowing more companies to adopt efficient and environmentally friendly design practices.

From the drawing board to the screen: an evolution that drives sustainability

The evolution of technical plans is not only a matter of efficiency, but also of sustainability. Digital environments have eliminated the need for paper and have significantly reduced the waste associated with the design process. In addition, digital optimization of designs allows for reduced consumption of materials and extended the useful life of industrial equipment.

Since its foundation, IES Soler has experienced this evolution from the inside. From the first hand-drawn plans to today’s collaborative 3D models, each stage has represented another step towards a more precise, efficient and sustainable industry.